Polyurethane Catalysts

Polyurethanes are polymers prepared by the reaction between an isocyanate (NCO functionality) and a polyol (OH functionality). These reactions are catalysed by metal organics and amines. Tin, Bismuth, Lead, Mercury, Zinc and Potassium organics, as well as tertiary amines, are used as the primary catalysts.

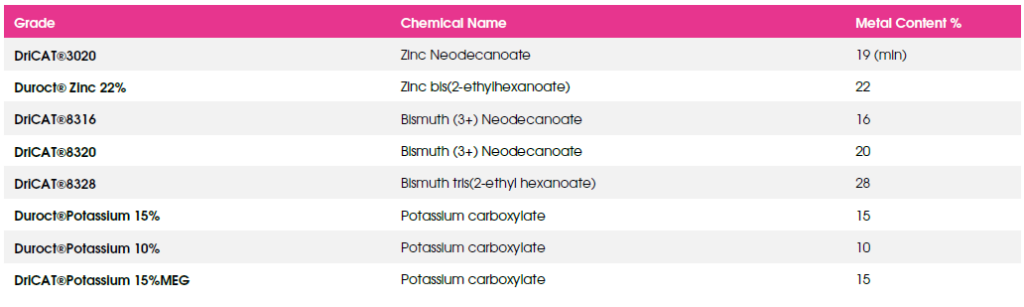

DriCAT®8320 and DriCAT®8316 – Bismuth Neodecanoate for flexible foams and elastomers

Duroct® Zinc 22% and DriCAT®3020 – Zinc 2-Ethylhexanoates and Zinc Neodecanoates as cure rate profile modifiers

Duroct® Potassium 10%, Duroct® Potassium 15% and DriCAT® Potassium 15%MEG – Potassium carboxylates -for rigid foams and unsaturated polyester resins in synergy with cobalt

The process of selecting a catalyst depends on several factors. Addition of metal catalysts in concentrations of ppm by weight has a profound effect on the reaction rate. In addition, catalyst selection will also depend on the cure profile requirements as they relate to the desired handling times and the properties of the cured product. Finally, environmental, and regulatory considerations cannot be ignored.

Grade

Chemical Name

Metal Content %

View Data Sheet

DriCAT®8328

Bismuth tris(2-ethyl hexanoate)

28

To arrange samples and further information please contact us

Tel: +44 (0)1530 561957

Email: [email protected]

To the best of our knowledge, the information contained herein is accurate and reliable as of the date of publication; however, we do not assume any liability whatsoever for the accuracy and completeness of the above information. Plastribution Speciality Chemicals makes no warranties which extend beyond the description contained herein. It is the customers’ responsibility to inspect and to test our products in order to satisfy themselves as to the suitability of the products to their particular purpose. The customers are responsible for the appropriate, safe and legal use, processing and handling our products.