SABO Surfactant Additives

Surfactant additives are used to improve properties and resolve potential issues with a range of polymers. We are pleased to offer the SABO range of materials including antistatic agents, pigment dispersion and antifogging agents.

Sabostat & Sabofog

SABOSTAT®

Most plastic materials tend to build up static charge due to very low conductivity (high surface resistivity).

Consequences of static charge build up vary from the most severe scenario like sudden electrostatic discharge in a flammable/explosive atmosphere or damage to packaged electronic goods, to less catastrophic but still problematic cases such as electrostatic adhesion in films, or simply undesired issues related to dust pick-up.

SABOSTAT® products are incorporated into plastic materials and, with a surface migration mechanism, increase surface conductivity, allowing for static charges to continuously release, therefore avoiding static charge build up.

SABOFOG®

Fogging refers to condensation of water vapor on the surface of a transparent plastic film (due to differences in temperature and humidity between the two sides of the film) in the form of small discrete droplets leading finally to loss of transparency.

In food packaging films, fogging causes loss in content visibility, and therefore in product attractiveness, as well as accelerating product quality deterioration.

In greenhouse films, fogging leads to slower plant growth, and also plant and fruit blemishing due to lens effect or hot water dripping.

Anti-fog additives typically comprise hydrophobic and hydrophilic chemical functional groups in a single molecule. This structural feature allows condensed water to form a transparent layer on the film surface instead of discrete droplets, therefore maintaining transparency. This in turn helps to maintain packaged food visibility and quality, and contributes to plant health in greenhouses.

Product selection from SABO’s anti-fog additives portfolio (including SABOFOG® MS, SABOFOG® ML, SABOFOG® PGS or SABOFOG® F1) enables our customers to design formulations and fine tune the anti-fogging effect according to film characteristics, usage conditions and effect durability.

Product Range

Polygylcerol Esters

Antifog

- SABOFOG ®PGS – Polyglycerol Stearate – PP packaging &PE greenhouse films

- SABOFOG®PGL – Polyglycerol Laurate – PE Sorbitan Esters – Antifog PE film

- SABOFOG®MS-P – Sorbitan Ester (Stearate) – PE greenhouse film

- SABOFOG®ML – Sorbitan ester (Laurate) – PE packaging film

Dispersing Agents – polyolefins, polyester, Polyurethanes, PVC

- SABO®NOL MO – Sorbitan monooleate

- SABO®LEN MOE – Sorbitan monooleate 20 EO

- SABOFOG®TOE – Sorbitan trioleate 20 Ely

- SABO®LEN MLE – Sorbitan Monolaurate 20 EO

Ethoxylated Amines

Antistatic – Medium Build-up of antistatic effect

- SABOSTAT®AL100 – Coconut Amine 2 EO

- SABOSTAT® ASE 3 – Tallow Amine 2 EO

- SABOSTAT®ASE 6 – Hydrogenated Tallow Amine 2 EO

- SABOSTAT® ASE – Stearyl Amine 2 EO

Ethoxylated Amine Esters

Improved long term antistatic and antifog effect

- SABOFOG ®F1 (food contact)

- SABOSTAT ®A300

Diethanolamides

- SABOSTAT® DELA – faster antistatic build up compared to ethoxylate amines

Ethoxylated Fatty Acids

- SABO®PAL OE 6 Antifog used in PE Packaging film for low colour

- SABO®PAL OE 9 Antifog used in PE Packaging film food contact

Dispersing Agents for Pigments and Fillers concentrates

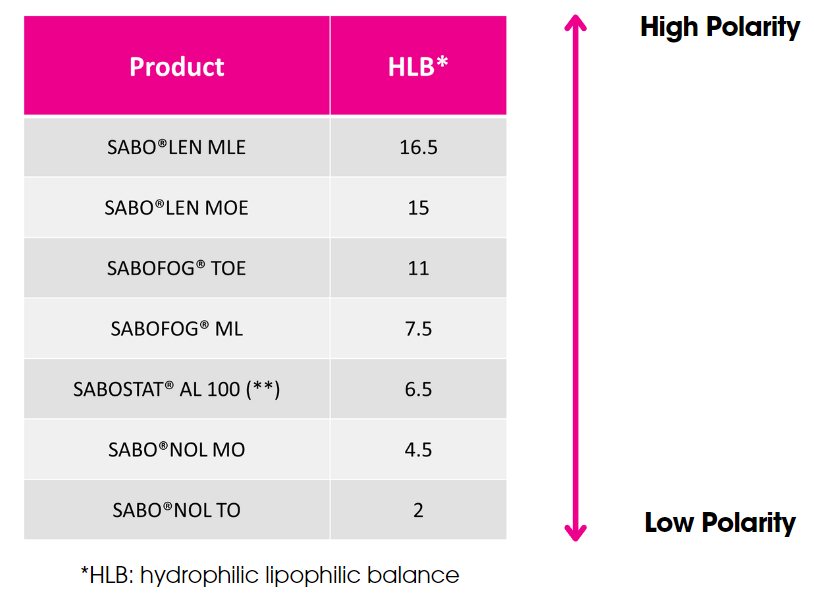

Combinations are regularly used to reach an intermediate polarity and optimum balance between “wetting” and “dispersing “behaviours. Example Ethoxylated high polar (High HLB) dispersant in combination with low polar (low HLB) dispersant

Liquid mix products are well established in liquid masterbatch materials mainly for PVC.PP, PE and polyurethanes but also used in PS, ABS, SAN, PA, EVA.

To arrange samples and further information please contact us

Tel: +44 (0)1530 561957

Email: [email protected]

To the best of our knowledge, the information contained herein is accurate and reliable as of the date of publication; however, we do not assume any liability whatsoever for the accuracy and completeness of the above information. Plastribution Speciality Chemicals makes no warranties which extend beyond the description contained herein. It is the customers’ responsibility to inspect and to test our products in order to satisfy themselves as to the suitability of the products to their particular purpose. The customers are responsible for the appropriate, safe and legal use, processing and handling our products.